As global manufacturers continue to look for reliable and cost-efficient production partners, Vietnam has steadily emerged as a strong destination for advanced metal fabrication. One area seeing meaningful adoption is robotic welding, where automation meets consistent quality.

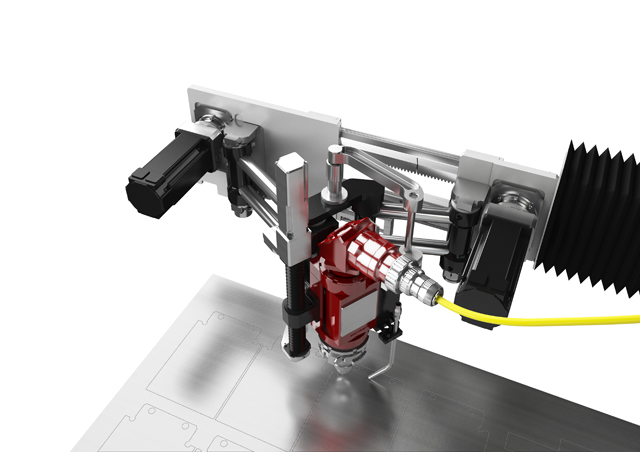

At Siba Industry, robotic welding is not positioned as a marketing trend, but as a practical tool to support repeatability, safety, and production stability. By integrating robotic welding systems into selected fabrication lines, Siba Industry ensures uniform weld quality across high-volume components while reducing human error and workplace risk.

The use of robotic welding also allows tighter control over welding parameters, helping maintain structural integrity and dimensional accuracy especially important for export-oriented projects serving markets such as North America, Australia, and Asia. Combined with experienced welding engineers and rigorous quality inspection, automation becomes a complement to human expertise rather than a replacement.

Vietnam’s competitive manufacturing environment, paired with skilled technical teams, enables Siba Industry to deliver robotic welding solutions that balance precision, scalability, and cost efficiency. This approach supports long-term partnerships with customers seeking consistent quality without unnecessary complexity.

Rather than pursuing automation for its own sake, Siba Industry focuses on applying robotic welding where it adds real value, supporting dependable production outcomes and meeting international standards with confidence.